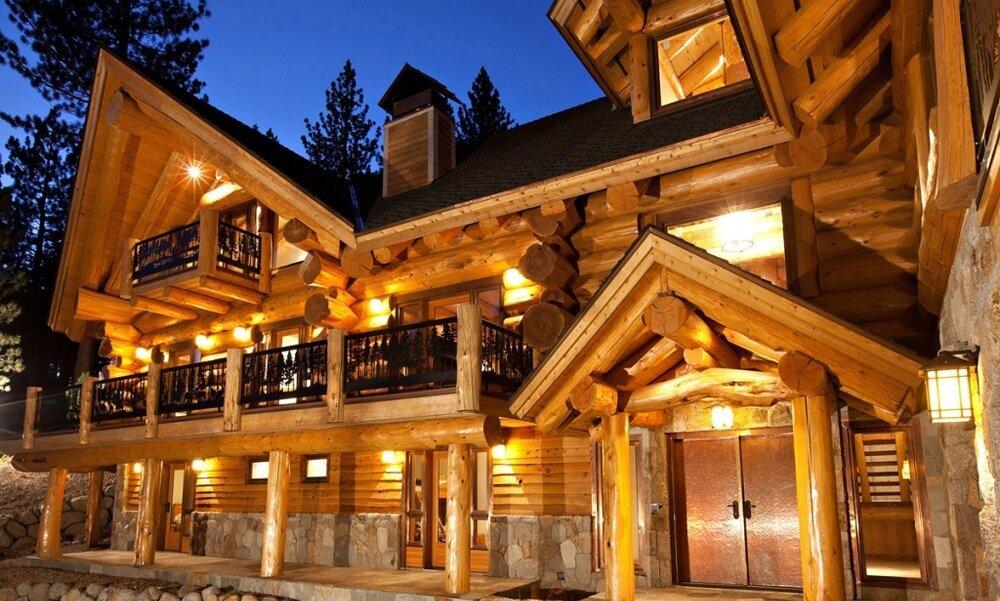

CEDAR AND LARCH PROJECTS

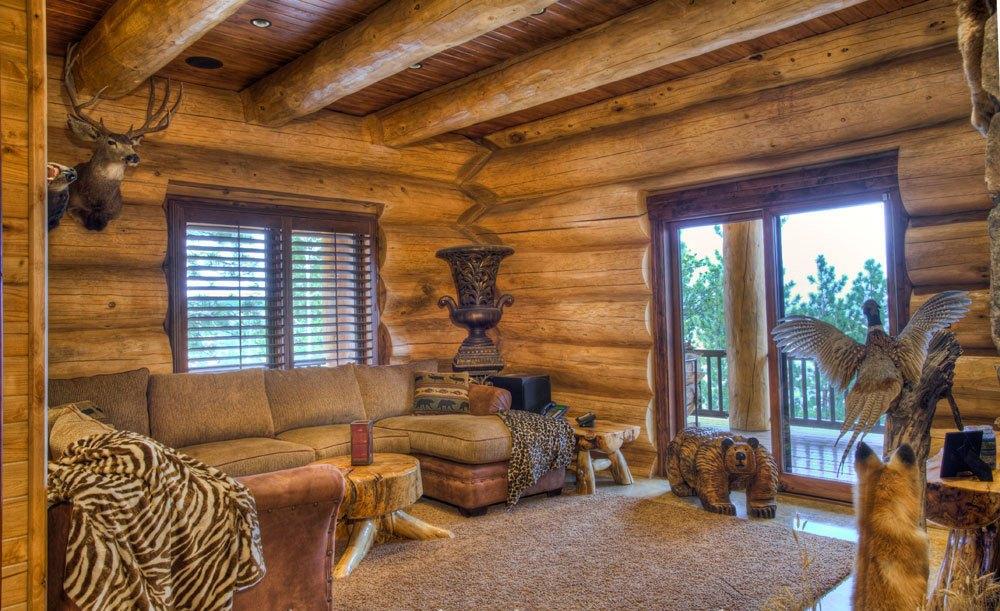

HAND-CARVED, LARGE LOGS HOUSES

WHAT WE ARE BUILDING

HOTELS, HOMES, AND ADMINISTRATIVE

BUILDINGS

BATHS AND SPA COMPLEX

OUR BUILDINGS

EVERY HOUSE IS AN INDIVIDUAL PROJECT

WHAT WE ARE BUILING FROM

A WOODEN HOUSE, THE KEY TO YOUR HEALTH

CEDAR PINE

LARCH

The thermal conductivity coefficient of Cedar is 0.095 W/(m • K). The density of Cedar is from 410 to 600 kg/m³ ( in the Middle 430 - 500 kg/m³ ). It has a dense ring around the edge of the trunk and a relatively soft inner part. It creates a healthy microclimate in the house. Cedar releases essential oils and phytoncides, which are natural substances with antibacterial properties that have a positive effect on the respiratory system and kill viruses and harmful microorganisms. According to scientists, the cedar microclimate in the room improves the quality and duration of life. A cedar house can last up to 200 years.

Larch has several advantages for home construction, which are related to its durability, moisture resistance, fire resistance, and environmental friendliness. These properties make larch a suitable material for building houses, saunas, terraces, and other wooden structures, especially in regions with high humidity and extreme temperature fluctuations. High density - Depending on the growing location and moisture content, larch wood can have a density ranging from 620 to 800 kg/m³. On average, it has adensity of 620 - 660 kg/m³. Hardness - in terms of hardness, larch is close to oak, resistant to scratches, dent and other external influences, negative effects of insects, microorganisms. Hardness also determines the durability of larch houses. For example, larch piles that were used in the construction of Venice Castles 300 years ago are still standing.

Moisture resistance

Natural resistance to moisture due to the high content of resins, which fill the pores of the wood and prevent water from penetrating, and phytoncides, which are natural antiseptics that inhibit the growth of mold, fungi, and bacteria.

Low hygroscopicity — the swelling of the wood due to water absorption is minimal, which is why larch is often used for window frames and outdoor flooring (such as on terraces). Larch, like cedar, also releases essential oils and phytoncides, but in smaller quantities. Larch is usually used to make houses, saunas, SPA complexes, the first rows of houses, decking boards, piles, and yachts. The thermal conductivity coefficient of Larch is 0.12 - 0.13 W/( m • K ). The service life of a Larch log house is up to 200 years.

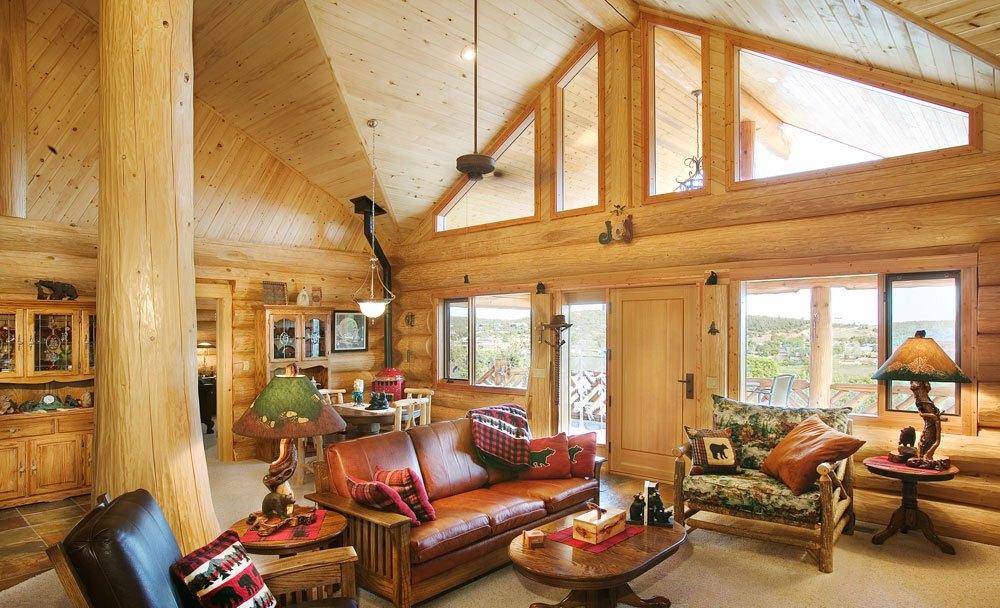

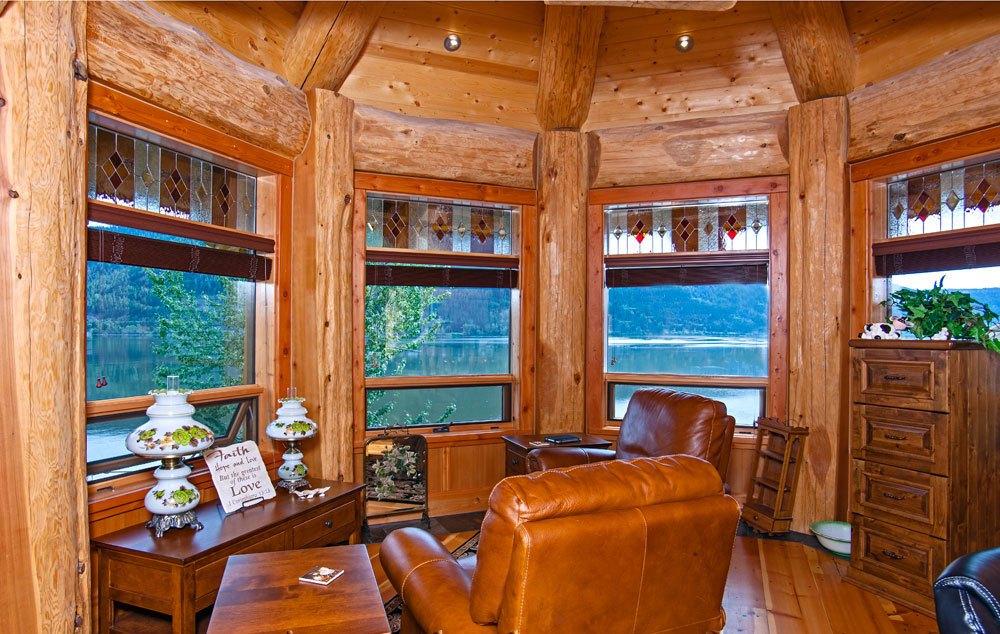

INTERIORS OF THE HOUSE

Wood is breathing

PROTECTING THE TREE

For hot climates, wood needs to be pre-treated and protected. For this, we use the best materials in the world.

Stages of protection of our wood:

1) Antiseptics. Used to protect wood from insects, mold and fire.

2) Protective compounds. Primers, Oils, Paints, Lacquer.

For example:

-Rubio Monocoat HybridWoodPro (provides protection of wood up to + 60 C from sunlight and sand).

-OSMO UV-Protection Oil – protection from UV radiation of the sun.

- Borma oils and so on.

It is important to ensure the protection of the tree from the sun's rays, drying out and mechanical effects of sand from sandstorms. Timber treatment of each wooden structure takes place every 2-5 years, depending on the condition.

3) The foundation for the house must be prepared with the consideration of anti-termite protection. With the exact observance of all these conditions, wooden houses will serve you for a long time and will be inherited by your children, grandchildren and great-grandchildren!

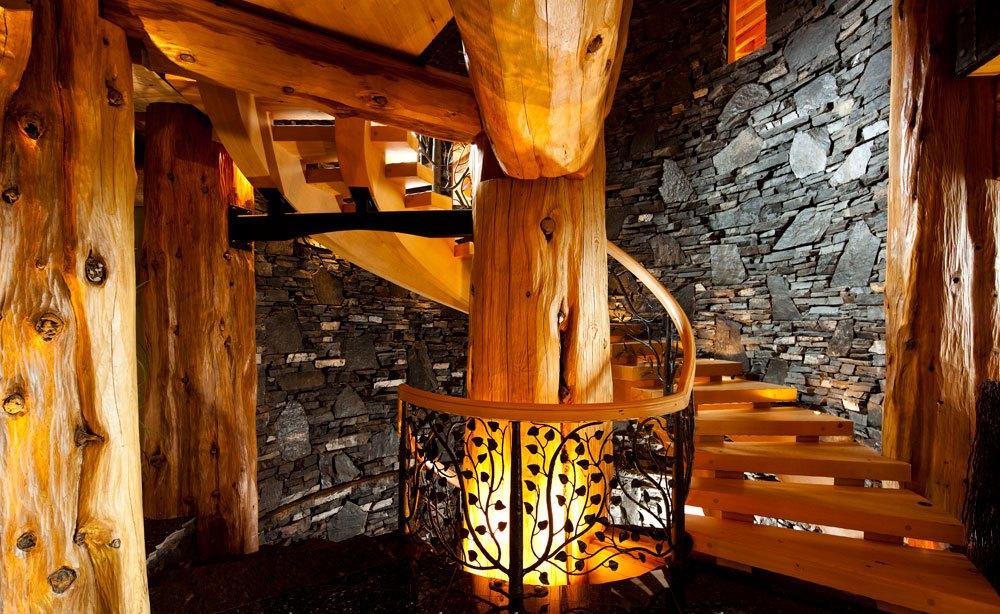

WOODEN STAIRS

ART IN WOOD

OAK

Regardless of the species, oak always has a beautiful texture.

Let's outline the main characteristics of oak wood:

The density ranges from 600 to 930, with an average of 700 kg/m3 (at a moisture content of approximately 15%), and can be higher for water oak and lower for bole oak. This indicates that oak is a medium-heavy wood;

The Brinell hardness is between 3.7 and 3.9, with an average of 3.3 for American varieties (red and white oak);

The compressive strength along the fibers is 56 MPa, and the static bending strength is 87 MPa;

The elasticity is about 12 GPa, which is higher than that of many other rocks. For comparison, the minimum elasticity is 6.2 GPa, and the maximum is 25 GPa;

The thermal conductivity along the fibers is 400 W/(m·K), and the thermal conductivity across the fibers is 200 W/(m·K);

The specific heat of combustion is 3240 kcal/l.

Due to its characteristics, oak is used in a very wide range of applications. These include building houses, shipbuilding, and manufacturing furniture, musical instruments, and household items.

SYCAMORE TREE

Density: 560 kg/m³.

Hardness: 4,180

N.Tensile modulus: 74.7

MPa.Elastic modulus: 8.90 GPa.

Compressive strength: 40.8 MPa.

Shrinkage: radial — about 6%, tangential — about 10%, volumetric — about 16%.T/R ratio: about 1.7.

THE ASH TREE

Density: average density is 650-690 kg/m³, and the density range is 410-860 kg/m³.

Bending strength: 105 N/mm².

Compressive strength: 50 N/mm².

Tensile strength: 130 N/mm².

Brinell hardness: 65 N/mm² along the grain, 37–41 N/mm² across the grain.

Thermal conductivity: 0.20 Kcal/m x h x C after heat treatment, 20% higher for untreated wood.

Natural moisture content: approximately 35% for freshly cut wood, up to 78% for the Manchurian variety.

Hygroscopicity: external moisture is poorly absorbed by ash lumber, but if it is exposed to a constantly humid environment for a long time, the wood begins to deform and warp. Combustibility: it ignites at a temperature of 400-630 °C.

THE CYPRESS TREE

Cypress wood is used for construction work, especially in cases where it comes into contact with the ground, as well as for external elements.

However, cypress timber as a building material is characterized by a high cost, as the tree grows very slowly..

The density in the dried state is about 470 kg/m³.

Despite its low density, it is durable and resistant to external influences.Ease of processing, both manual and machine.

When processing cypress, sharp cutters and light movements are recommended to avoid breaks.

Nail and screw retention - the wood retains nails and screws well.Resistance to decay.

Old cypresses are rated as resistant or very resistant to decay, while the wood of young trees is rated as moderately resistant.Resistance to moisture. Cypress wood does not warp or crack during drying, it is not afraid of the population

COMPARISON CEDAR OR LARCH

Cedar releases more essential oils and phytoncides than Larch, i.e. has greater health benefits and a more intense aroma. Cedar has a lower thermal conductivity coefficient (0.095 W/(m • K)) than Larch ( 0.12 – 0.13 W/( m • K )). Thus, inside a Cedar house will be cooler in hot season than in a Larch house. However, this parameter depends on the thickness of the log. Larch has a higher density (620 - 660 kg/m³) than Cedar (430 - 500 kg/m³). For this, we use the highest quality materials.

HOTELS, RESTAURANTS, AND SPA COMPLEX

REST WITH THE SOUL

FIREPLACES IN A WOODEN HOUSE

IN THE EVENING BY THE FIREPLACE

COMBINATION OF WOOD AND STONE

HEAT AND COLD

WOODEN BATHHOUSE AND SPA COMPLEX

WINTER AND SUMMER

STAGES OF WORK

WORK WITH PROFESSIONALS